CNC laser machining employs a superior-frequency laser beam to slice or engrave materials. In contrast to EDM machining, laser machining can work for machining non-metals just together with metals.

Regularity and Repetition: CNC machines supply consistent replications of equivalent parts with precise requirements anytime, making them The perfect solution for mass production. Despite complex designs, CNC machining makes certain Every aspect continues to be just like its predecessor in visual appeal.

Precision CNC tolerance will not be standardized. Tolerance concentrations vary according to the production method. The number of decimal areas within a tolerance worth demonstrates the measurement’s rigor. Here are the various kinds of tolerance measurement systems:

There are various other prices, like the Expense paid for the designer for the pc Aided Manufacturing (CAM) blueprint, the hourly labor price of a precision machinist based upon the precision machinist’s techniques, and a lot more.

Due to extensive selection of applications, CNC precision machining requires a variety of machinery and equipment. Allow me to share the machinery and equipment:

That summer months, Bredikhin and several other organization associates traveled to Taiwan, where by they joined Yu for steak dinners, cigars and also a fishing journey, As outlined by social media marketing posts. One particular article from the journey was captioned: “Russian associates come to Taiwan.”

If you more info want dependable precision machining providers, get in contact with 3ERP, and you'll receive a quotation inside of 24 several hours.

On the Main of modern manufacturing is accuracy and performance; CNC Precision Machining plays an indispensable job below. Used from aerospace to health care equipment, it happens to be an integral technology.

In CNC machines there will have to have the hardware, program system, and studies to do the machining operations. the primary hardware is Microprocessor and so you can deal with function and peripheral interaction involving gadgets.

For illustration, There's a selection of the volume of axes in precision machining equipment. A multi-axis machine can Charge two to thrice greater than a 3-axis machine evaluating hourly fees.

As an illustration, in the case of wind turbines, precision CNC machining is necessary to make the blades balanced enough to rotate Along with the wind.

CNC milling is actually a machining procedure that works by using computerized controls and rotating multi-stage cutting tools to remove materials from the workpiece and develop a custom-built part or product or service. This method is appropriate for machining many different materials, like metal, plastic, glass, and wood, in addition to producing a number of custom-built parts and merchandise.

Precision grinders are among the last manufacturing processes after machining parts/components. In precision grinding, abrasive grinders (or grinding wheels) develop a perfectly flat floor with an exceptionally sleek finish on the machined parts.

In most cases, the answer to how these things are made is the same - precision CNC machining. CNC strategies are the muse stone for modern businesses, making parts in an automated manner at unbelievable production speeds.

Rick Moranis Then & Now!

Rick Moranis Then & Now! Melissa Joan Hart Then & Now!

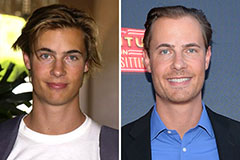

Melissa Joan Hart Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Heather Locklear Then & Now!

Heather Locklear Then & Now! Teri Hatcher Then & Now!

Teri Hatcher Then & Now!